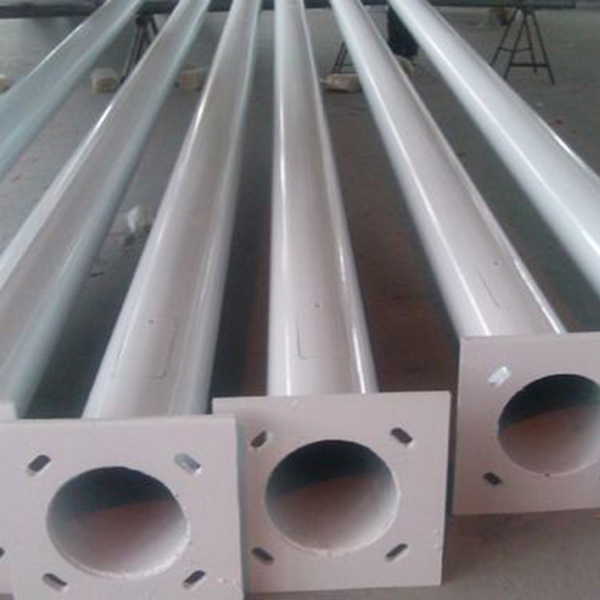

High quality Hot-dip galvanized street light pole

Technical Parameters

| Name | Technical Specs |

| Pole System Lifepan | More than 20 years |

| Height | 4M-12M |

| Material | Steel,Q235,Hot-Dip Galvanized.Plastic Coated,Rust Proof,With Arm,Bracket,Flange,Fittings,Cable,Etc |

| Top Diameter | 60mm-90mm |

| Bottom Diameter | 120mm-180mm |

| Pole Thickness | 2.0mm-4.0mm |

| Painting | Wanted Color |

| Resistant to Wind | ≥160KM/H |

| System Certification | ISO9001,CE&EN,RoHS,IEC,SONCAP,FCC |

| Warranty | 10 Years |

| Loading Qty | 80PC/40'HQContainer |

| Payment | 30%Deposit&Banlance Before Shipment |

| Delivery Time | Usually 15-25Days after Order,Big order need check again |

| Customizable | Customizableaccording to different requirements |

Brief Introduction of Lighting Pole

Lighting Pole is one important part in street lights system and solar street lights sysytem

Our light pole structures have been successfully applied in more than 114 Countries

Solar Street Lights Pole Selling Points:

◆ More Range of Light Pole 2.5M-15M,High Mast Pole 15M-40M

◆ All kinds of shapes of Tapered,Round,Square,Octagon,Etc

◆ We can make the drawing as your wanted designed poles and arms

◆ Antirust Treatment:Hot Dip Galvanization Or HDG With Powder Coating

◆ Color For Choosing:Grey,Black,White,Blue,Green,Etc.You can contact us for Color Card

Features

Single arm / Double arm street light pole

Height from 4 meter to 18 meter, suitable for highway, Road way etc.

Shape: Polygonal, Conical or Columniform

Material: Normally Q235B/A36, Minimum Yield Strength ≥ 235 N/mm² or Q345B/A572, Minimum Yield Strength ≥ 345 N/mm². As well as Hot rolled coil from ASTM A572 GR65, GR50, SS400.

Match lamp power: 20W to 400W (HPS/MH), 220V (+-10%)/50HZ

Surface treatment: Hot dip galvanized Following ASTM A 123, color polyester power or any other standard by client required.

Joint of Poles: Slip joint, flanged connected.

Length of per section: Within 14 meter once forming

Thickness: 2mm to 5mm according to client’s requirement.

Production Process: Raw material test → Cutting →bending →Welding →Dimension verify →Flange welding →Hole drilling →sample assemble → surface clean→ Galvanization or powder coating, painting →Recalibration →Packages

Packages: Packing with plastic paper or according to client’s request.